Need to keep products air-tight or safe from contamination?

Whether it’s food, jewellery, electronics, or crafts, using a heat sealer will ensure your products are packaged properly – protecting them from damage during transit or storage.

Heat sealers provide a quick and easy solution for sealing a variety of polypropylene and cellophane bags, presenting your products in a more appealing way to potential customers.

By securely sealing bags, these machines can also help extend the shelf-life of your products – minimising waste. But how do you use a heat sealer correctly?

As a proud distributor of Hacona heat sealers, allow the team at Get Me Packaging to guide you through the process, step-by-step.

How to use a heat sealing machine in 5 simple steps

1. Select the appropriate heat sealer for your application

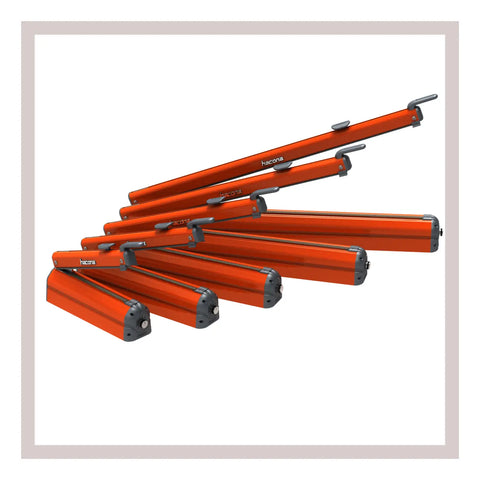

From impulse heat sealers to constant heat seal machines, there are many types of heat sealing machines on the market – all of which offer unique features, capabilities, and dimensions.

Hacona heat sealers are impulse sealers that work by pushing a button to activate the heating elements, whereas constant heat sealing equipment provides a ‘constant’ cycle of heat.

To determine the most suitable machine for your budget and packaging needs, consider the size, thickness, and material of the bags you’ll use.

It’s also worth taking into account how much available space you have and whether a hand-held sealer will suffice or you need a work stand and foot pedal too.

2. Safely position your machine

After choosing a heat sealer, the next step is to decide where it will go.

Ideally, it needs to be placed on a flat and level surface – near a suitable power source – away from liquids and flammable materials to prevent it from tipping over or being damaged.

Position your heat sealing machine at a comfortable height with the handle in easy reach to avoid strain or injury.

If space permits, consider buying a compatible work stand and foot pedal to help speed up the sealing operation and reduce fatigue.

3. Fill and prepare the bag

Your heat-sealable bag needs to be clean and free from dirt, dust, and contaminants to ensure a long-lasting seal for your products.

This will prevent any gaps or weak spots from forming in the seal – preventing leaks during storage or transportation – and retain the freshness and quality of your products for longer.

Once your bag is ready, place it over the sealing area of your heat sealer and double-check that the bag is flat and there are no wrinkles or folds.

4. Adjust the sealing time

Hand-held impulse sealers are incredibly versatile tools, used by various industries to seal a wide range of items.

The Hacona heat sealers we supply offer fully adjustable sealing times for different packaging materials and thicknesses – creating a strong, air-tight seal.

Thinner bags can usually be sealed with a short blast of heat while thicker bags typically require more time to seal.

A short seal time may not seal the bag properly, leading to leaks or damage. If the seal time is too long, the bag may melt or warp.

Top tip: use the dial to set a shorter sealing time and gradually increase it until you achieve a strong, secure seal.

5. Seal the bag

After positioning and preparing your poly bags and adjusting the timer, all that’s left to do is seal them up.

To do so, all you need to do is use the ergonomic handle to lower the sealing jaw and apply sufficient pressure to engage the heating element.

A Hacona heat sealer has an LED above the seal timer dial that turns red when the sealing jaw comes into contact with the lower part of the machine. This indicates that the heat seal process has begun and will go yellow when the seal is complete.

Before you release the sealing jaw, allow the bag to cool down to prevent accidental tears or damage to the seal. If necessary, use the integrated cutting knife slider to trim the bag to size and then take the bag out.

Get the most out of your heat sealer

Making sure you use your heat sealer correctly is crucial, but so is keeping it in tip-top condition.

Impulse heat sealers require regular maintenance to perform smoothly and efficiently – providing reliable and consistent sealing for many years to come.

To prevent any buildup of debris or residue on the sealing element, remember to give your heat sealer a quick wipe-down after every use. And if you spot any cracks or signs of wear or damage, you’ll need to replace the element.

For more information about the accessories and replacement parts available for Hacona heat sealers, talk to our experts on 01246 488 999.